Everything You Need to Know About Engine Rebuilds

Key Takeaways

- Summary of What an Engine Rebuild Involves: Rebuilding an engine means tearing it down, cleaning it up, and putting it back together with new or refurbished parts. It’s like giving your engine a second chance at life, especially if it’s been showing signs of wear and tear.

- Main Benefits of Rebuilding an Engine: Rebuilding an engine is often easier on the wallet than buying a brand-new one. Plus, it gives you the opportunity to tweak performance and ensure the engine meets your exact needs.

- Essential Considerations Before Starting a Rebuild: Before you dive in, you’ll want to weigh the pros and cons of a rebuild versus just replacing or repairing the engine. Consider the costs, the tools you’ll need, the potential risks, and the time you’ll have to commit.

Introduction to Engine Rebuilds

When I think about engine rebuilds, I see them as more than just a mechanical process—they’re a way to breathe new life into a vehicle that might otherwise be headed for the scrap yard. Whether you’re restoring a classic car or just trying to extend the life of your daily driver, an engine rebuild is a deeply rewarding experience. It’s challenging, yes, but the satisfaction of hearing that engine roar back to life after a rebuild is something every car enthusiast should experience.

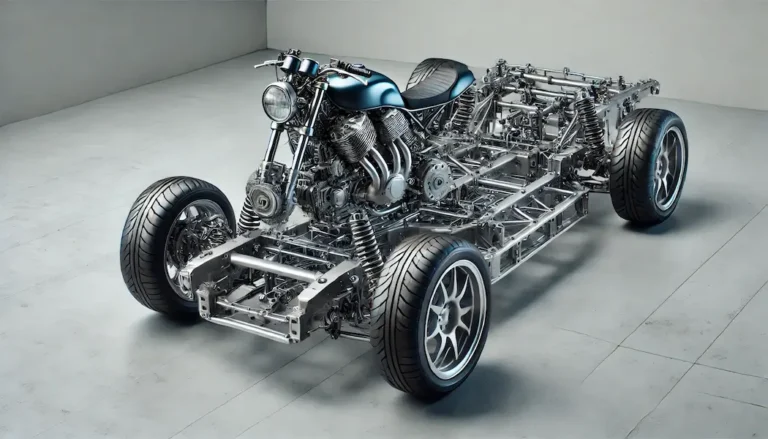

What is an Engine Rebuild?

You’d consider a rebuild when your engine’s worn out or damaged but still has some life left in it—it’s the middle ground between repair and replacement. An engine rebuild involves tearing the engine down, cleaning it up, inspecting it, and then putting it back together with new or refurbished parts to make it run like new again. It’s often the best option when you want to fix serious issues without going all the way to an engine replacement.

Signs Your Engine Needs a Rebuild

I’ve been around engines long enough to know that they don’t just fail overnight. They give you signs—if you’re paying attention. Keep an eye out for things like burning too much oil, weird knocking sounds, low compression, or an engine that just won’t stop overheating. These are all telltale signs that your engine might be crying out for a rebuild.

The Difference Between Engine Rebuilding, Repairing, and Replacing

There are several paths you can take when dealing with a failing engine. I’ve walked down all of them, and here’s what I’ve learned:

- Engine Rebuilding: This is the middle ground—you’re not starting from scratch, but you’re getting an engine that’s practically new. It’s a comprehensive overhaul, replacing worn-out parts and restoring the engine to its original performance.

- Engine Repair: Repairs are okay for small stuff, but sometimes it’s just like slapping a band-aid on a bigger issue. This typically involves addressing specific problems, like replacing a gasket or fixing a valve.

- Engine Replacement: If a rebuild isn’t for you, you could always go with a new or remanufactured engine instead. This is usually more expensive but less labor-intensive.

Types of Engine Rebuilds

Partial Engine Rebuild

A partial engine rebuild, sometimes referred to as a top-end rebuild, focuses on specific components of the engine, such as the cylinder head, valves, and timing chain. It’s a good option when the lower part of the engine is still in good working order. It’s quicker and less expensive than a full rebuild, but only works if the bottom end of the engine is still solid.

Complete Engine Rebuild

A complete engine rebuild, also known as a bottom-end rebuild, involves overhauling the entire engine. This includes replacing or refurbishing the pistons, crankshaft, camshaft, bearings, and all seals. It’s a bigger job and more costly, but it’s the way to go when your engine has significant wear or damage throughout.

The Engine Rebuilding Process

Initial Assessment and Diagnosis

Before starting an engine rebuild, a thorough assessment and diagnosis are crucial. This process typically involves:

- Visual Inspection: Checking for obvious signs of wear or damage, such as leaks, cracks, or warped components. I’ve learned to trust my gut during this stage—sometimes, the smallest crack can spell trouble.

- Compression Testing: Measuring the engine’s compression to identify potential issues with the valves, piston rings, or head gasket.

- Diagnostic Tools: It’s amazing what modern tools can reveal—sometimes things even a seasoned mechanic might miss. Using advanced diagnostic tools to analyze engine performance and pinpoint specific problems is a must.

Disassembly of the Engine

Once the diagnosis confirms that a rebuild is necessary, the engine is disassembled. This step involves:

- Labeling and Organizing Parts: Carefully labeling all parts to ensure they can be reassembled correctly. I’ve learned this the hard way—there’s nothing worse than losing track of where a part belongs!

- Removing Major Components: Taking apart the engine piece by piece, starting with external components like the alternator and moving towards the internal components like the crankshaft.

- Precautions: Ensuring that delicate parts are handled with care to prevent damage and contamination.

Cleaning and Inspection of Engine Parts

After disassembly, each part of the engine is thoroughly cleaned and inspected. Key steps include:

- Cleaning Methods: I like to get every part squeaky clean, whether it’s using chemicals, ultrasonic cleaning, or a good old-fashioned scrub. This helps remove dirt, grime, and old lubricants from engine parts.

- Inspection for Wear and Damage: Checking for cracks, warping, and wear that could compromise engine performance. Microscopic inspection and measurements are often used to determine if parts can be reused.

Replacing and Repairing Parts

During the inspection, any parts that are beyond repair are replaced. Common parts that typically need replacing include:

- Pistons and Rings: Worn-out pistons and rings are replaced to ensure proper sealing and compression.

- Bearings and Seals: Replacing worn bearings and seals is crucial for preventing leaks and maintaining engine efficiency.

- Gaskets: All gaskets are usually replaced to ensure that there are no leaks in the engine.

Reassembly and Testing

The final phase of the rebuild involves reassembling the engine and testing its performance. This includes:

- Step-by-Step Reassembly: Carefully putting the engine back together, ensuring all components are correctly installed and torqued to specification. This is where patience really pays off—rushing here can undo all your hard work.

- Testing: Once assembled, the engine is tested to ensure it runs smoothly and meets performance standards. Hearing that engine start for the first time post-rebuild? Pure magic.

Tools and Equipment Needed for an Engine Rebuild

Essential Tools

An engine rebuild requires a variety of tools, including:

- Socket and Wrench Sets: Used for removing and installing engine components.

- Torque Wrench: Ensures that bolts and nuts are tightened to the correct specifications. My torque wrench has been my trusty companion through countless rebuilds—getting those bolts just right is crucial.

- Engine Hoist: Necessary for safely lifting and moving the engine during the rebuild process.

Specialty Tools

Depending on the engine type, additional specialty tools may be required:

- Piston Ring Compressor: Essential for installing new piston rings without damaging them.

- Valve Spring Compressor: Used to remove and install valve springs safely.

- Cylinder Hone: Helps in refurbishing cylinder walls to ensure proper piston ring sealing.

Safety Equipment

Safety is paramount during an engine rebuild. Essential safety gear includes:

- Safety Glasses: Protects eyes from debris and harmful substances.

- Gloves: Protects hands from chemicals and sharp edges.

- Hearing Protection: Necessary when using loud power tools.

Costs Involved in an Engine Rebuild

Cost of Parts

Parts can really vary in price depending on what kind of engine you’re working with. Typical costs include:

- Pistons and Rings: $100 to $500 per set.

- Bearings: $50 to $200 for a complete set.

- Gaskets and Seals: $100 to $300 for a full gasket kit.

Labor Costs

Labor costs for an engine rebuild can be significant, especially if performed by a professional:

- Professional Labor: Typically ranges from $1,000 to $3,000 depending on the complexity of the rebuild and the shop’s rates.

- DIY Labor: The cost is primarily your time and effort, but it can save a significant amount of money if you have the necessary skills.

DIY vs. Professional Rebuilds

Deciding whether to do the rebuild yourself or hire a professional depends on several factors:

- Experience Level: Rebuilding an engine requires significant mechanical knowledge and skill. I’ve always been hands-on, but I understand that it’s not for everyone.

- Tool Availability: DIYers need to have access to all the necessary tools. If you’re up for the challenge and have the time, I’d recommend giving a DIY rebuild a shot. There’s nothing quite like the satisfaction of doing it yourself.

- Cost: Doing it yourself is cheaper, but if something goes wrong, it might end up costing you more in the long run. I’ve seen friends save thousands by doing it themselves, but I’ve also seen a few who ended up paying double when they had to bring it to a shop afterward.

Timeframe for an Engine Rebuild

Average Time Required

The time required for an engine rebuild varies depending on the type of rebuild and the mechanic’s experience:

- Partial Rebuild: Typically takes 15 to 30 hours.

- Complete Rebuild: Can take 40 to 60 hours or more. I’ve spent entire weekends in the garage, but it’s always worth it in the end.

Factors Affecting the Timeframe

Several factors can influence the timeframe:

- Parts Availability: Waiting for parts to arrive can cause delays.

- Complexity of the Engine: More complex engines require more time to rebuild.

- Experience Level: How long a rebuild takes really depends on what you’re doing and how experienced you are.

Benefits of Rebuilding an Engine

Cost Savings

Rebuilding an engine is often more cost-effective than purchasing a new one:

- Comparison with New Engines: A new engine can cost $4,000 to $10,000 or more, whereas a rebuild typically costs $2,000 to $5,000. For me, the financial savings are significant, but what I value most is the ability to keep a good engine going.

- Longevity: A well-rebuilt engine can last as long as a new one, offering a similar lifespan for a lower cost.

Extending the Life of Your Vehicle

Rebuilding an engine can significantly extend the life of your vehicle:

- Preserving the Vehicle: A rebuild allows you to keep your existing vehicle running, avoiding the cost and hassle of buying a new one. I’ve always preferred to rebuild rather than replace—it’s my way of honoring the car’s history and the memories made in it.

- Maintaining Performance: A rebuilt engine can restore your vehicle’s performance, making it feel like new again.

Customization Opportunities

Rebuilding an engine offers opportunities for customization:

- Performance Upgrades: Components can be upgraded during a rebuild to enhance horsepower, torque, or fuel efficiency. I’ve often taken this opportunity to tweak things—whether it’s adding a bit more horsepower or optimizing fuel efficiency.

- Tailored Specifications: The engine can be tailored to specific driving needs, whether it’s for daily commuting, racing, or off-roading.

Risks and Challenges of Engine Rebuilds

Potential Pitfalls

Rebuilding an engine is a complex task that carries certain risks:

- Incorrect Assembly: One wrong move when putting things back together and you could end up with a dead engine. Trust me, I’ve been there—double-checking every step is crucial.

- Overlooking Damage: Failing to identify and address all issues during the rebuild can result in recurring problems.

Risk of Additional Damage

Improper handling during the rebuild process can cause further damage to the engine:

- Contamination: Introducing dirt or debris during assembly can cause serious damage to engine components.

- Improper Torqueing: Not tightening bolts to the correct specifications can lead to leaks or component failure.

Overcoming Challenges

To successfully rebuild an engine, consider these tips:

- Follow a Detailed Manual: Use a service manual specific to your engine to ensure proper procedures. I never start a rebuild without one by my side—it’s like having a roadmap to success.

- Take Your Time: Rushing through the process can lead to mistakes. Patience is key. Every time I’ve tried to rush, it’s come back to bite me.

- Seek Professional Help When Needed: If you’re unsure about any part of the process, consult a professional. There’s no shame in asking for help—it’s how we all learn.

Case Studies: Successful Engine Rebuilds

Case Study 1: Classic Car Restoration

A successful engine rebuild on a classic 1967 Mustang involved a complete teardown and rebuild of the V8 engine. The owner opted for performance upgrades, including a high-performance camshaft and pistons, resulting in improved horsepower and torque, while maintaining the car’s classic feel. I’ve tackled a similar project myself, and the joy of bringing a classic back to life is unmatched.

Case Study 2: Performance Enhancement

A performance enthusiast rebuilt the engine of a Subaru WRX, focusing on boosting turbo efficiency and enhancing fuel delivery. The result was a significant increase in power output, making the car competitive on the track while still being reliable for daily driving. I remember doing something similar on a friend’s WRX—every tweak brought us closer to perfection on the track.

Alternatives to Engine Rebuilds

Engine Replacement

Replacing an engine is an alternative to rebuilding. It involves installing a new or remanufactured engine:

- Pros: Quick solution, comes with a warranty, ensures all-new components.

- Cons: More expensive than a rebuild, may not be cost-effective for older vehicles.

Engine Repair

In some cases, repairing specific engine components might be more appropriate than a full rebuild:

- When to Consider: Minor issues like gasket failures or valve problems that don’t affect the entire engine.

- Cost: Generally lower than a rebuild, but may not address all underlying issues.

Buying a Remanufactured Engine

A remanufactured engine is another option:

- What It Is: An engine that has been rebuilt by professionals and is sold as a ready-to-install unit.

- Considerations: Often comes with a warranty, but can be as costly as a new engine depending on the make and model.

Frequently Asked Questions (FAQs) About Engine Rebuilds

How Long Does an Engine Rebuild Last?

A properly rebuilt engine can last as long as a new engine, often up to 150,000 to 200,000 miles or more, depending on the quality of the rebuild and maintenance practices.

Can Any Engine Be Rebuilt?

Most engines can be rebuilt, but the feasibility depends on the extent of the damage, availability of parts, and the engine’s overall condition. Some rare or highly damaged engines may not be suitable for rebuilding.

Is Rebuilding an Engine Worth It?

Rebuilding an engine is often worth it if the vehicle has sentimental value, if a replacement engine is prohibitively expensive, or if you want to maintain specific performance characteristics.

What Are the Signs of a Bad Engine Rebuild?

Signs of a bad rebuild include persistent leaks, unusual noises, poor performance, and frequent engine check lights. These issues may indicate improper assembly or overlooked damage during the rebuild process.

Thanks for checking out this article on EngineEcho.com! Hope you found this article: "Everything You Need to Know About Engine Rebuilds" helpful! If you liked it and want to dive into more car engine topics, head over to our homepage. There's always something new to discover in the world of engines. Enjoy your reading journey!

Check out our previous article: What to Do When the Check Engine Soon Light Comes On